Primer on HEAT … for buildings, water and industry

From Bloomberg

When we think of global energy consumption, I imagine most of us think of two things. The first is power plants, be they fossil fuel-fired thermal plants, or zero-emissions wind and solar, or nuclear. The second is transportation, ranging from tiny personal scooters to container ships with an engine that could power a small city. These two sectors account for more than half of all energy consumption, with transport alone using up a third.

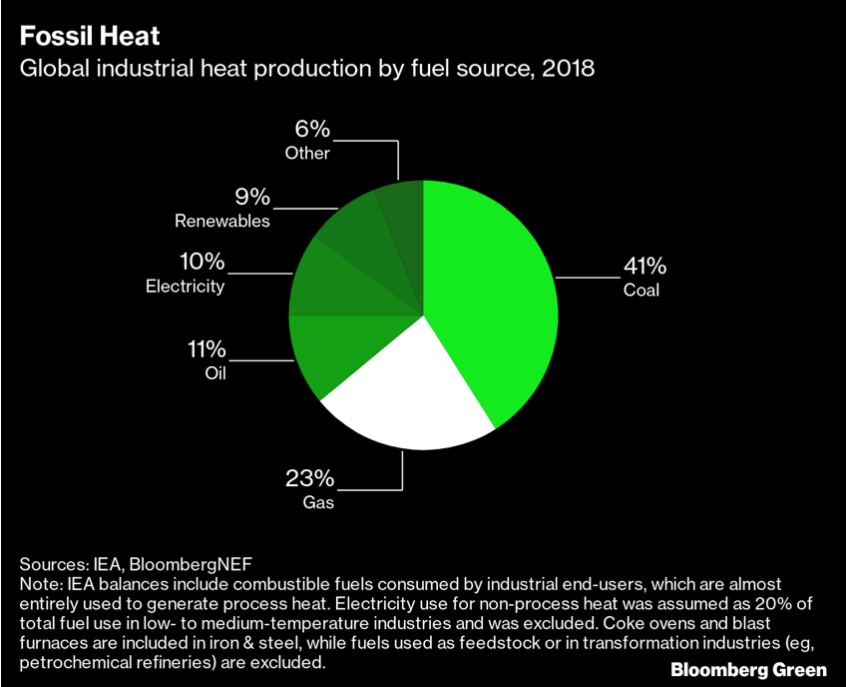

There is another sector though that is nearly as big but commands a tiny fraction of the public or research attention as the rapidly-changing transport sector: heat. Global industrial heat production accounts for 29% of all energy consumed by end users like homes, industries, and agriculture. However much I examine this data (all the time), I still am struck by it: almost one-third of human energy consumption goes to making things hot, on an industrial scale.

Heat production is a major source of greenhouse gas emissions and much of it is in what are known as “hard-to-abate” sectors where, for technical and economic reasons, lowering emissions can be very challenging. Doing so is both essential and increasingly possible, as my colleagues at BloombergNEF and the World Business Council for Sustainable Development explore in a new white paper.

Industrial heat brings to mind metallurgical processes like steelmaking, copper smelting, or cement production. They are indeed a major portion of industrial heat demand, and today meeting that demand is overwhelmingly the job of hydrocarbon fuels, in particular coal and gas. These processes are not only hot, but they often require constant production and close contact between the source of production and the site of consumption.

Steelmaking and petrochemical transformation and similar intensive processes make up a major chunk of industrial heat demand, but there is a very long tail of other industrial heat uses. Food services need steam for peeling vegetables, dry heat for baking, and boiling water for, well, boiling. Paper and packaging production requires heat for drying pulp into finished products. Furniture making needs steam for bending and shaping wood. The apparel industry needs heat for bleaching and dyeing fabric. The list is long.

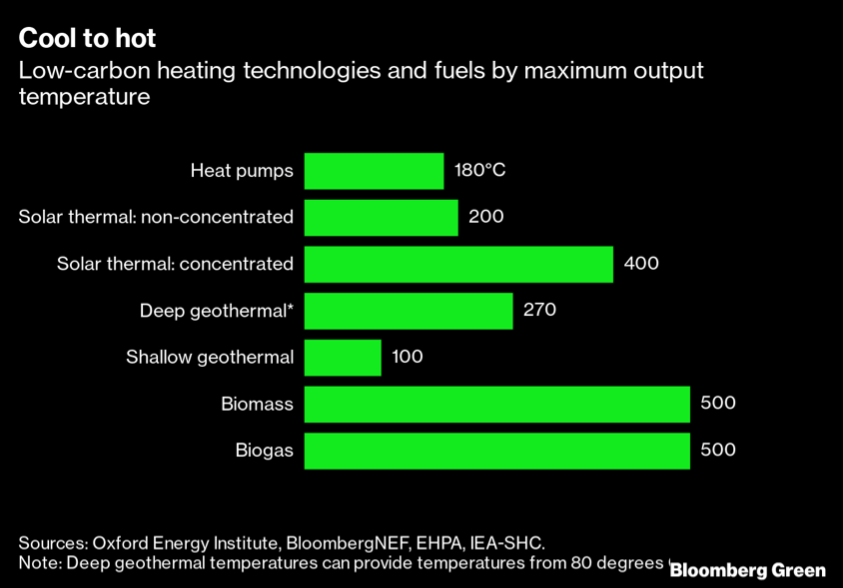

Importantly, though, these processes often separate the source of heat from its point of use — that is, heat is created in one place, and sent to another on-site for use. That means that the technologies used for generating that heat can be swapped into processes more readily, with multiple technologies having multiple applications. The same technology can provide heat for different end uses depending on site or market, and by the same token, different technologies can provide the heat for identical applications in the site or market.

Importantly, too, fuels other than coal, gas, and oil can meet the demand for that lower-temperature. It can be met with biomass, as the pulp and paper industry uses, or biogas, or with a solar thermal system that concentrates sun to boil water. It can be provided by geothermal power, or even with an industrial heat pump. Below the higher temperatures needed for heavier industrial applications, there are many technologies available to meet demand.

However, the relative abundance of suitable technologies has not translated to widespread adoption, for a simple reason. Coal and gas are readily available and they are inexpensive. Moving to an alternative heat source in an existing industrial system requires not only a conscious decision, it requires investment as well. Economics alone cannot pull the low- and zero-carbon lower temperature heat technologies into the market.

But thanks to this recent research, we have an idea of where and how a concerted effort towards new technology can make a difference. BloombergNEF and WBCSD determined that the 19 countries (plus the European Union) of the G-20 comprise 80% of global low- to medium-temperature heat demand. Of those 20 markets, six countries make up 46% of total demand — China, South Korea, France, Germany, Italy, and the UK. They have favorable market conditions, such as relatively high market prices for gas which translates to higher prices for gas-fired heat. They’re also favorable because they’re mature markets that are able to adopt these heat applications — they have a ready network of installers and maintenance providers. Finally, and most applicably elsewhere, they have strong policies that help new heat technologies along, including a price on carbon which makes fossil-fueled options less economic.

BNEF’s white paper found that globally, economies are three times more likely to have an electricity decarbonization policy than a heat decarbonization policy. There is room for heat policy to catch up, such as the carbon price mentioned above, and incentives for deployment of some earlier-stage technologies such as higher-temperature heat pumps that have a greater potential market than today’s models.

Fortunately too, companies themselves are making net-zero emissions commitments which, given their scope and scale, will necessitate renewable heat applications in the future. This source of demand will drive production and ultimately lower costs. Those companies willing to explore every application of renewable heat today can help create the markets and technologies of tomorrow.

Nathaniel Bullard is BloombergNEF’s Chief Content Officer.